Products Description

Customized plan book printing is a process that integrates paper selection, design layout, printing technology and binding methods, aiming to create a personalized plan book that meets user needs. The following is a detailed introduction:

Paper selection

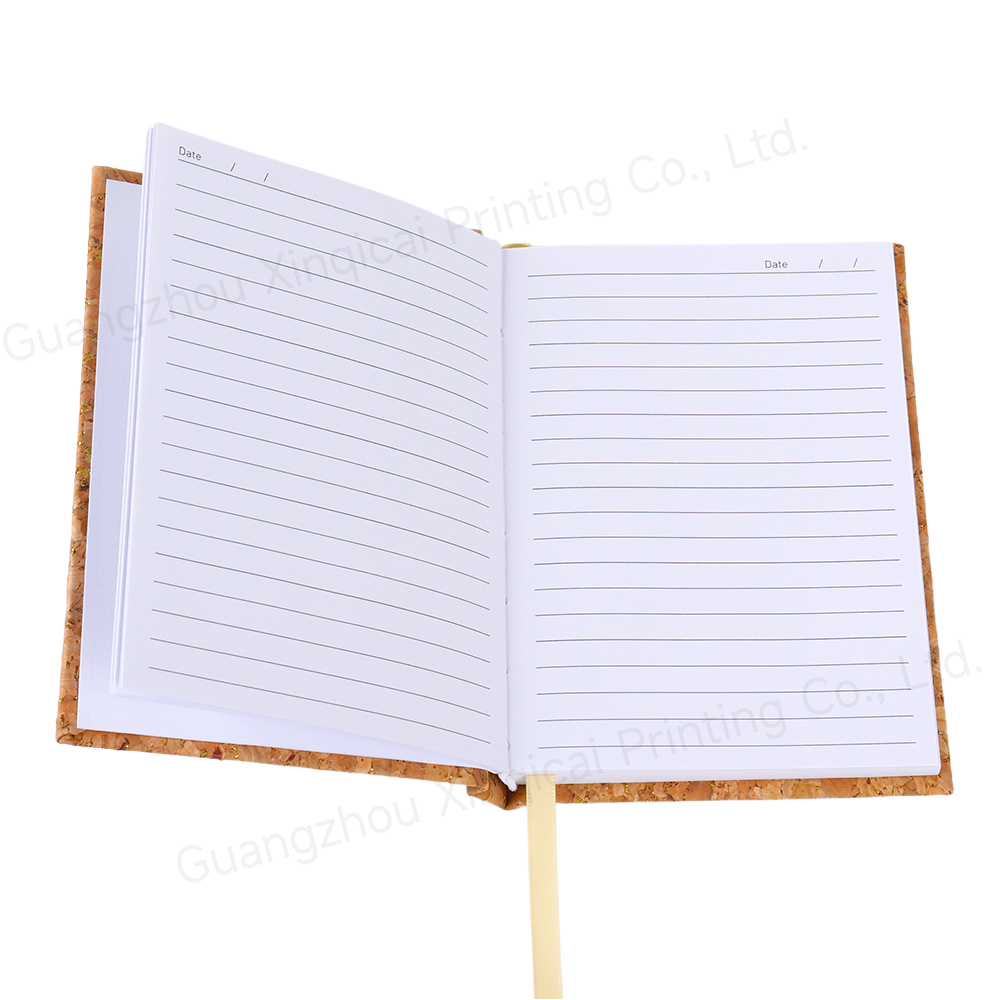

Dolin paper: fine texture, good writing performance, can reduce writing friction, effectively avoid ink penetration, and make the recorded content clear and readable. It is a commonly used paper for the inner pages of the plan book.

Pure cotton paper: with natural fiber texture and high toughness, it can withstand multiple flipping and is not easy to be damaged. It is suitable for plan books that require a long storage time.

Coated paper: smooth surface, bright colors, suitable for the cover of the plan book, can show good texture, and is often used in cover designs that need to highlight visual effects.

Matte powder paper: thicker than coated paper, also suitable for the cover of the plan book, can show a certain high-end texture.

Design layout

Inner page design: the layout can be customized according to user needs, and modules such as task lists, schedules, project planning tables, monthly plans, and weekly plans can be added to facilitate users to organize information and plan time and tasks reasonably.

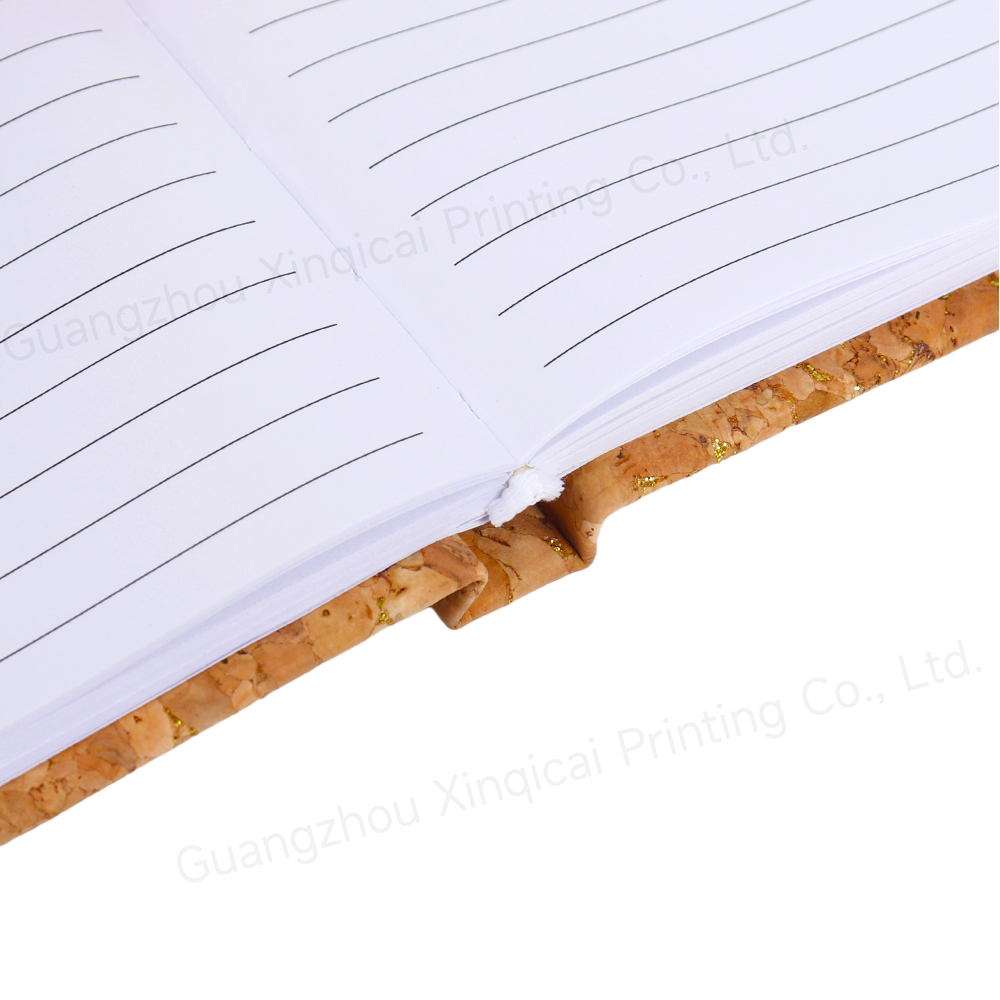

Cover design: The cover is the facade of the planner. A simple and personalized cover can enhance the beauty and stimulate the desire to use it. You can print the brand logo, personal name or favorite pattern on the cover. You can also choose hot stamping, hot silver and other processes to add texture, or highlight the exclusiveness through embossing.

Printing process

Offset printing: Suitable for mass production, stable printing effect, high color reproduction, it is a good choice for printing of planners with high quality requirements and large quantities.

Digital printing: No plate making is required, high flexibility, suitable for small batch customization, fast delivery, suitable for users with limited budgets or pursuing highly personalized designs.

UV printing: It can make the pattern of the planner more three-dimensional and enhance the visual effect through local glazing. It is often used for the processing of important patterns on the cover or inner pages.

Hot stamping / hot silver process: It can leave gold or silver logos and texts at specific positions on the cover or inner pages to enhance the grade and exquisiteness of the planner.

Binding method

Glue binding: It is to glue the cover and inner pages together with glue. The operation is simple and easy. It is suitable for thicker planners and has a relatively flat appearance.

Saddle stitching: After folding the printed pages in half, use wire to staple them together from the spine. It is suitable for thinner planners, which is convenient to flip through and has a relatively low cost.

Thread binding: Use thread to thread the cover and inner pages together. It has a simple and elegant style and is often used in some planners with traditional style or pursuing unique texture.

Loose-leaf binding: Use a loose-leaf clip to fix the inner pages. Users can add or replace the inner pages at any time according to their needs. It is highly flexible and convenient to adjust the content and structure of the planner.

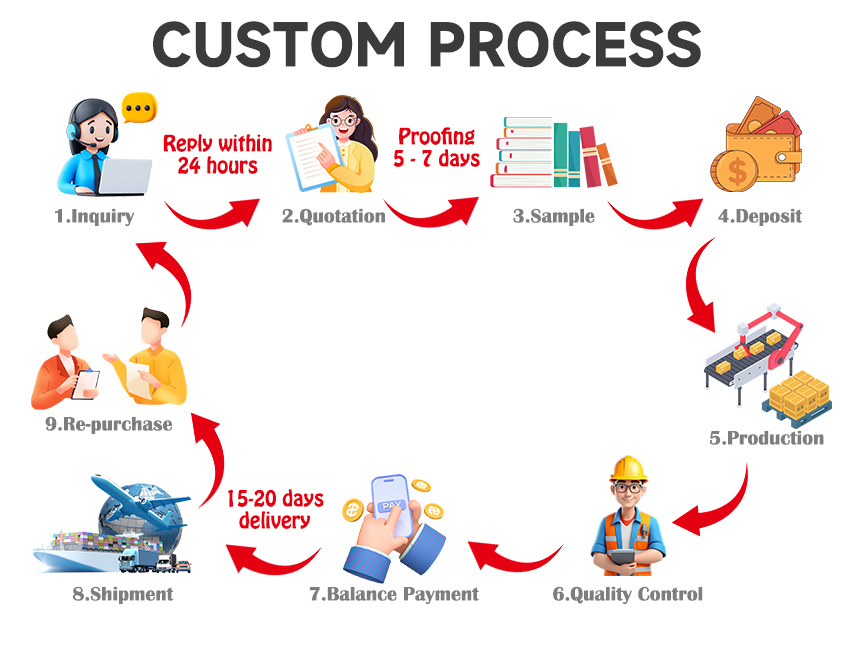

Customization process

Demand communication: The customer communicates with the printer to determine the specifications, quantity, printing materials, delivery time and other information of the planner, form a customized order form and sign and confirm it by the customer.

Design draft production: The designer makes a preliminary design draft according to customer needs and sends it to the customer for confirmation. After the customer confirms, the design file is saved for production.

Material procurement: The procurement department purchases paper, ink and other materials according to the order requirements to ensure that the material quality meets the standards.

Production preparation: After the materials arrive, they are inspected and put into the warehouse. The production department formulates a detailed production plan and arranges production equipment and personnel.

Printing production: Print according to the design and production plan, strictly control each link, conduct quality inspection after completion, and rework unqualified products in time.

Product packaging and delivery: Pack the qualified plan books, select the appropriate packaging method and logistics according to customer requirements, and arrange delivery.

After-sales service: After the product is delivered, collect customer feedback, and coordinate and deal with any problems in a timely manner to improve customer satisfaction.