Products Description

Customized journal printing is a systematic work that combines content presentation needs, visual design, process selection and mass production, aiming to create exclusive printed products for enterprises, institutions, academic groups or individuals that meet specific positioning (such as academic journals, corporate internal publications, industry magazines, community publications, etc.). The following is a detailed introduction from the aspects of core elements, process selection, process management, etc.:

I. The core positioning and specification determination of customized journals

The first step of customizing journals is to clarify their purpose, audience and style, which directly determines the subsequent specifications, design and process selection:

Purpose classification:

Academic journals: focus on rigor, need to clearly present papers, charts, references, and have high requirements for printing accuracy and paper durability.

Corporate internal publications: used for internal cultural communication and employee communication, the style can be flexible and diverse, and often integrated into the corporate VI (visual identification system).

Industry magazines: for practitioners in specific industries, need to highlight industry information and case analysis, and may involve a large number of pictures and data charts.

Community/institutional publications: such as school magazines and association journals, the style tends to be personalized, and can be integrated with community logos, event records, etc.

Basic specifications:

Size: Common sizes include 32-mo (portable small magazine), 16-mo (standard magazine size, such as 210mm×285mm), and large 16-mo (210mm×297mm). Special sizes (such as square and special shapes) can also be customized.

Page number: It needs to be determined according to the content volume, usually an even number of pages (printing and typesetting requirements). If the number of pages is too small (such as less than 24 pages), saddle stitching can be selected. If the number of pages is large (such as more than 48 pages), it is recommended to bind or lock the glue binding.

Printing color: The inner pages can be printed in black and white (low cost, suitable for pure text content), monochrome printing (partial embellishment) or full-color printing (rich in pictures and texts, good visual effects); the cover is mostly full-color, and the recognition needs to be highlighted.

II. Paper selection: Differentiated matching of cover and inner pages

The texture and performance of paper directly affect the reading experience and durability of the journal, and need to be reasonably matched according to the content and budget:

Cover paper:

Both protection and visual impact need to be taken into account. Coated paper or matte paper with a thickness of 157g, 200g, 250g, and 300g are commonly used (coated paper has high gloss and is suitable for picture display; matte paper has a soft texture and is suitable for text-based covers).

High-end journals can choose special paper (such as textured art paper and environmentally friendly recycled paper) to enhance uniqueness.

Inner page paper:

Text-based journals: 60g-80g Daolin paper (smooth writing, thin paper, suitable for large amounts of text) or offset paper (cost-effective, clear printing) can be selected.

Illustrated journals: 105g-128g coated paper (high color reproduction, suitable for pictures and charts) is required to avoid blurred or see-through images.

For those who are environmentally friendly: you can choose FSC certified paper (forest sustainable certification), recycled paper, etc.

III. Design and layout: fit the positioning, and take into account both beauty and practicality

The design and layout of the journal needs to balance "information transmission efficiency" and "visual appeal". The core points include:

Cover design:

Highlight the journal name, issue number, and core theme, and can integrate logos (such as institutional LOGO, journal emblem), and convey the journal style through color and font (such as academic journals use calm tones, youth journals use bright colors).

Inner page layout:

Text layout: font size (10-12pt is usually used for the main text), line spacing (to ensure comfortable reading), and paragraph spacing must be unified; academic journals must reserve fixed format areas for citations, notes, and references.

Graphic layout: Pictures must be high-definition (resolution ≥300dpi) to avoid stretching and deformation; data charts (such as bar charts, tables) must have clear lines and clear color distinctions.

Column number design: Commonly used are single column (mainly text) and double column (combination of graphics and text to save space), which can be adjusted according to content density.

IV. Printing process: improve texture and recognition

According to the journal positioning and budget, you can choose basic or advanced processes to enhance visual effects and texture:

Basic printing process:

Offset printing: suitable for large-scale (more than 500 copies) printing, stable color reproduction, low cost, and is the mainstream choice for journal printing.

Digital printing: no plate making is required, suitable for small batches (less than 100 copies) or urgent orders, and can achieve personalized content (such as printing different names in each journal), but the cost of large batches is high.

Specialized process (mostly used for cover):

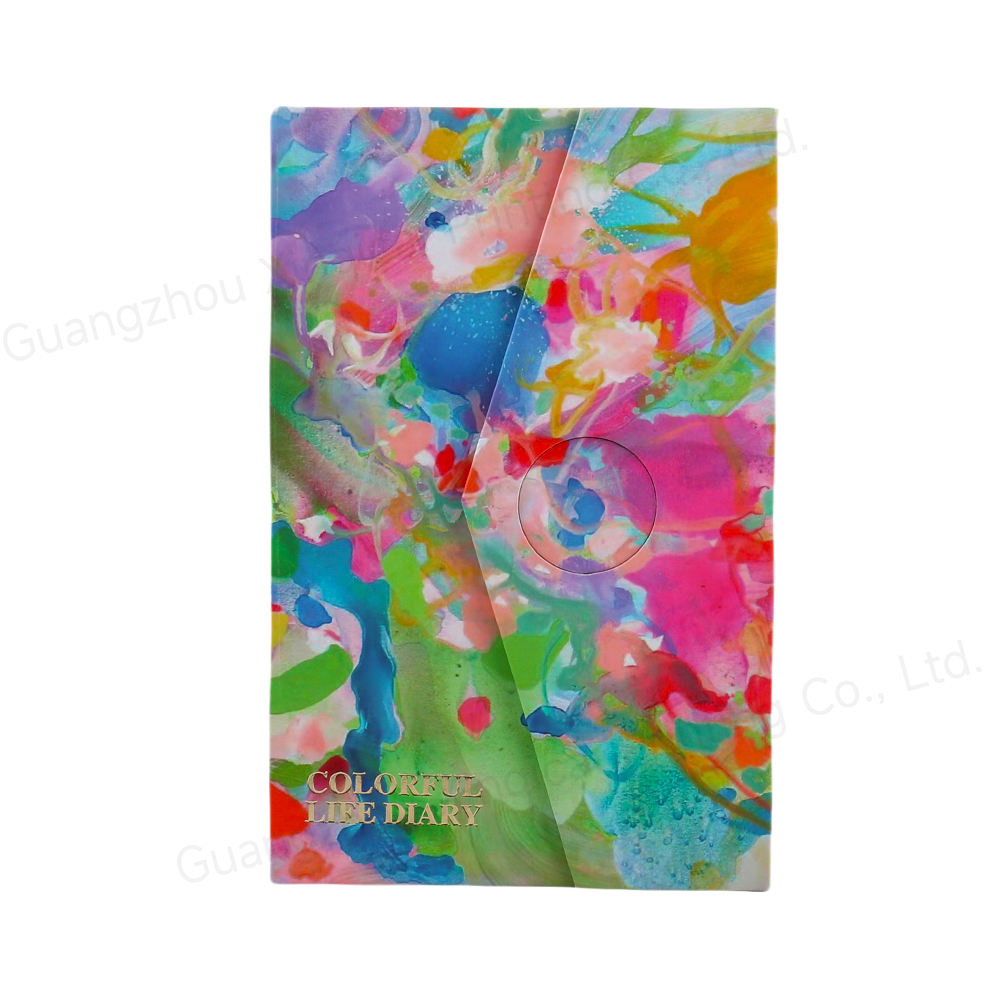

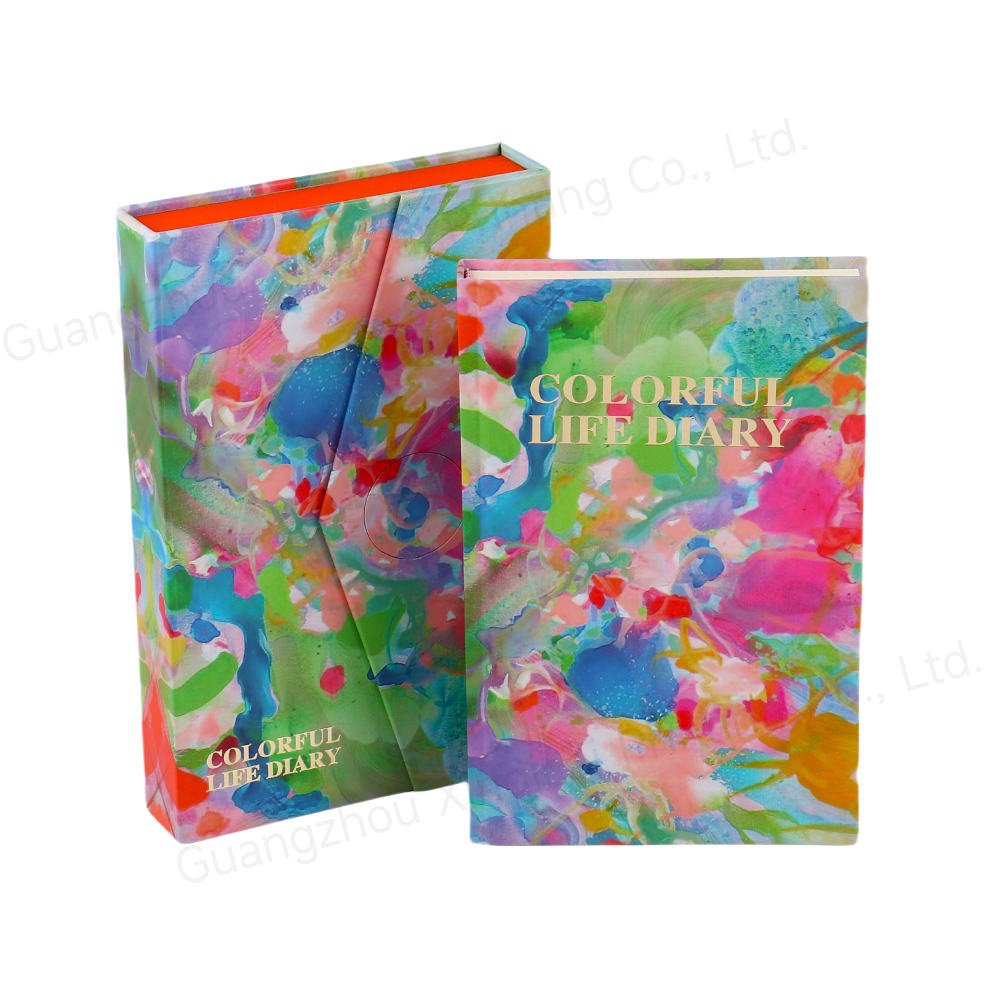

Hot stamping/hot silver stamping: hot stamping metal foil (gold, silver, copper, etc.) on the cover text and LOGO to enhance the grade, suitable for high-end journals or commemorative publications.

UV glazing: partial or overall coverage of UV varnish to form a bright surface convex effect, enhance the three-dimensional sense of the pattern (such as cover title, pattern), and improve wear resistance.

Embossed/debossed: through mold pressing, the cover text or pattern presents a three-dimensional convex and concave sense, and the details can be highlighted without ink, which is suitable for simple style journals.

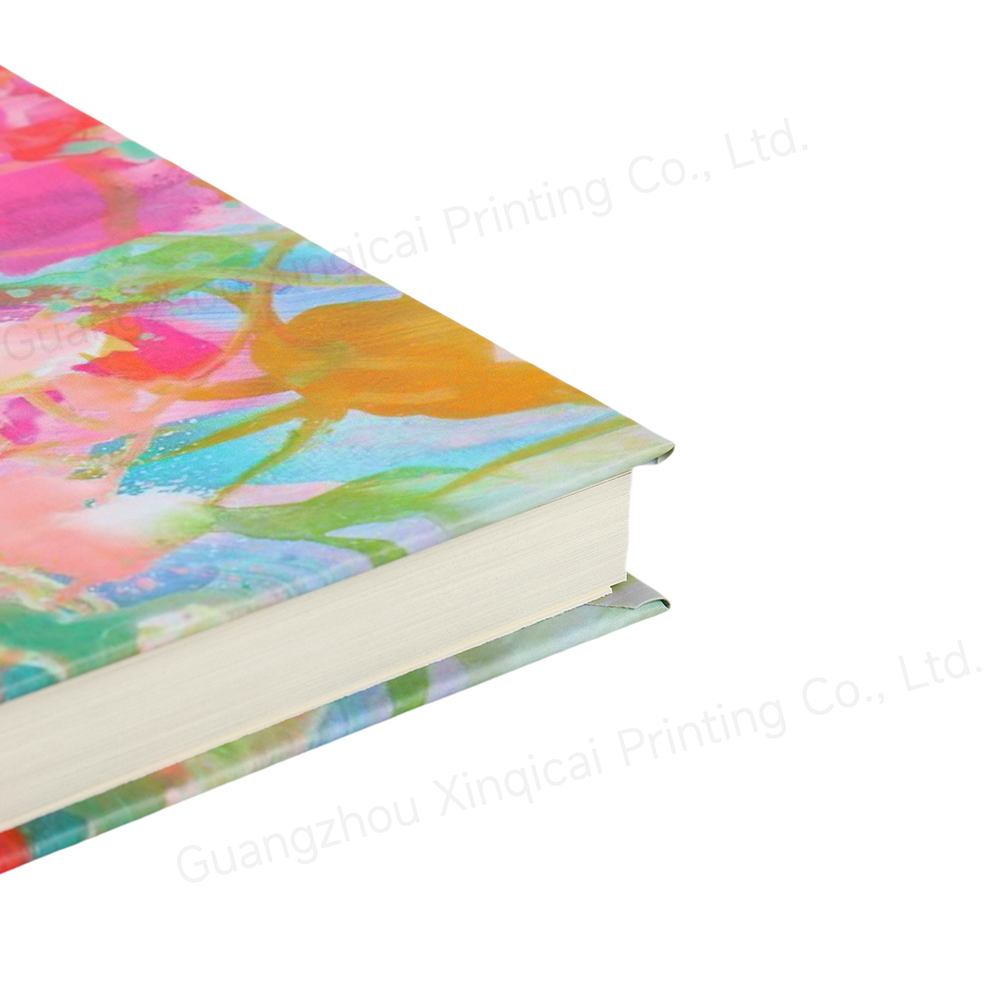

Lamination: The cover is coated with a bright film (to increase gloss) or a matte film (scratch-resistant and wear-resistant, with a soft texture) to protect the paper from damage and extend its service life.

Drumming/embossing: Make a bulge or texture (such as leather texture, cloth texture) on the cover to enhance the touch, suitable for high-end corporate internal publications or industry magazines.

V. Binding method: Choose according to thickness and purpose

The binding method affects the reading experience and durability of the journal, and needs to be selected in combination with the page number and usage scenario:

Saddle stitching: After folding the pages in half, use wire to bind from the spine. It is suitable for journals with a small number of pages (≤48 pages) and thin and light (such as weekly and monthly reports). It has low cost and fast binding, and can be completely flat for reading.

Glue binding:

Wireless glue binding: Use glue to glue the inner pages to the cover. It is suitable for journals with medium page numbers (50-200 pages). It has a smooth appearance and moderate cost, but thick books may have loose pages.

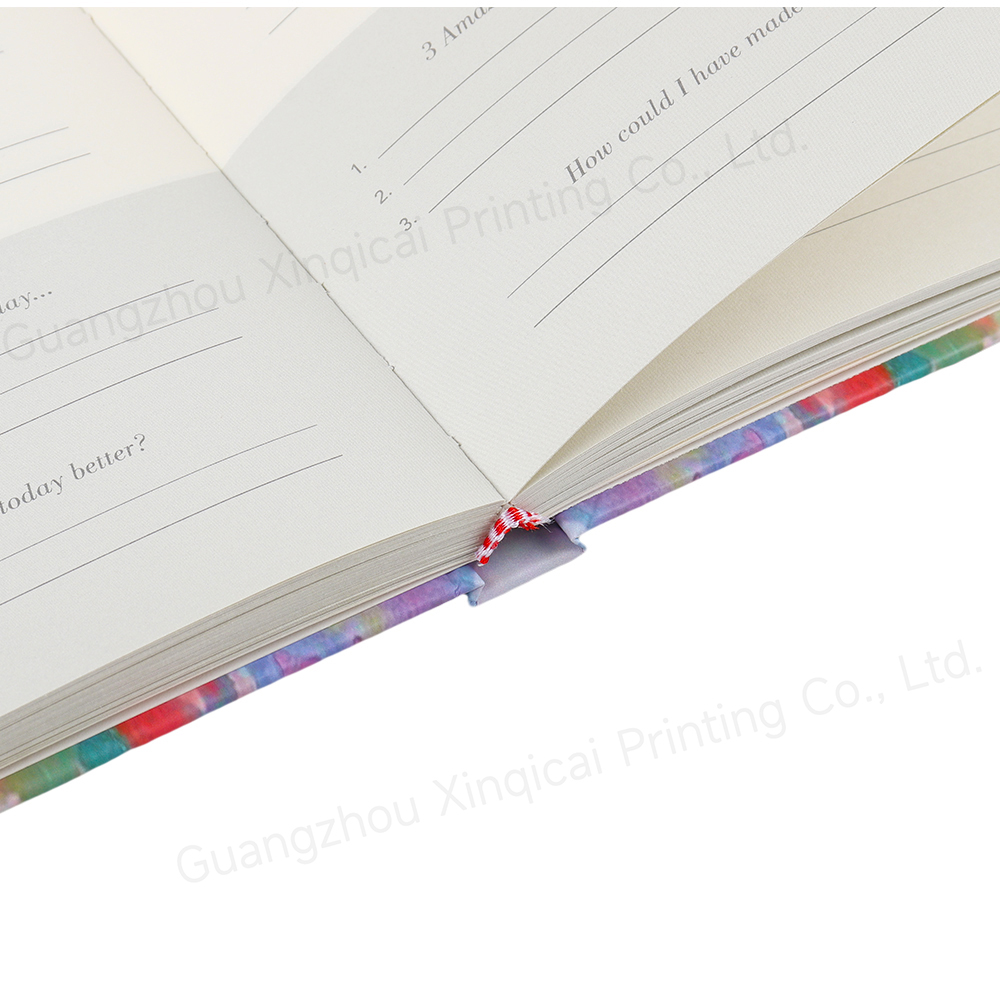

Sewing and gluing: The inner pages are first fixed by sewing, and then the cover is glued and glued. It is suitable for thick journals (≥150 pages). It is highly firm and can be laid flat, suitable for long-term storage (such as academic journals and yearbooks).

Hardcover: The cover is made of hard cover (cardboard covered with special paper or leather), and the inner pages are bound with the hard cover after sewing. It has a high-end texture and is suitable for high-end journals (such as industry yearbooks and commemorative special issues). It has a high cost and a long production cycle.

Loose-leaf binding: The inner pages are fixed with ring binding or clips, and pages can be added or removed at any time. It is suitable for journals with updated content (such as corporate dynamic manuals), but the appearance is slightly inferior.

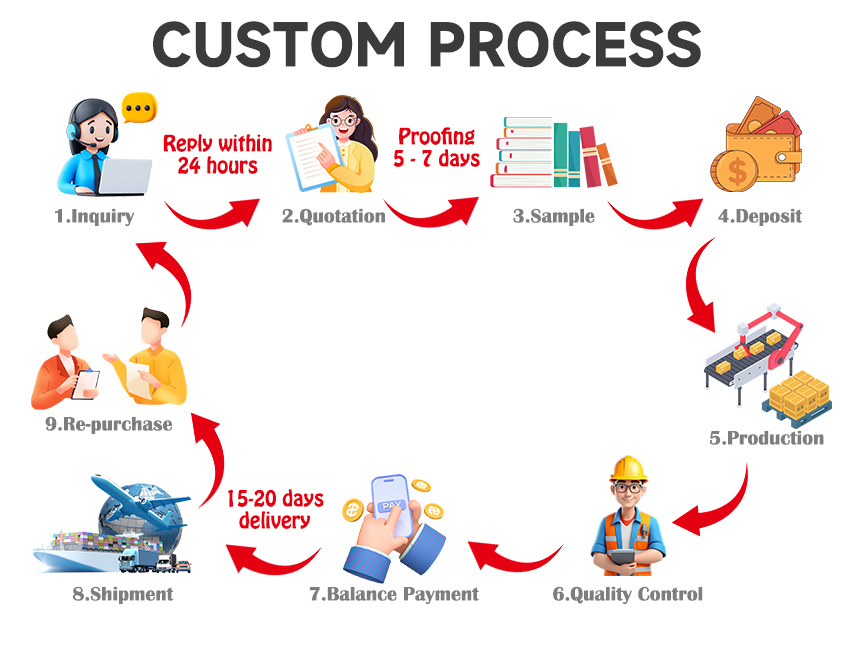

VI. Customization process: full-cycle management from demand to delivery

Demand communication and solution confirmation:

The customer clearly defines the journal positioning (purpose, audience), specifications (size, page number, printing color), quantity, budget and delivery time.

The printer provides samples (paper, process, binding effect) for the customer's reference, and signs a contract after confirmation to clarify the rights and responsibilities (such as design draft requirements, quality standards, and breach of contract clauses).

Design submission and review:

The customer provides a design draft (must meet printing standards: CMYK mode, resolution 300dpi, bleed position 3mm), or entrusts the printer to design (extra design fee).

The printer conducts pre-press review (check text clarity, image resolution, color mode, etc.) to avoid printing errors.

Proofing confirmation:

Make small samples (1-3 copies), the customer checks the content, color, and process effect, and signs and finalizes after confirmation (proofing may be charged, and large orders can often be deducted).

Mass production:

The printer arranges printing, cutting, binding, post-processing (such as lamination, hot stamping) according to the final draft, and conducts quality inspection throughout the process (spot check of color deviation, binding firmness, etc.).

Delivery and after-sales:

Packaging (such as plastic sealing, boxing) as agreed in the contract, delivery by logistics or self-pickup, and provide logistics tracking information.

After-sales support: If there are quality problems (such as wrong pages, missing printing, inconsistent process), negotiate rework or compensation; provide reprinting service (small batches can be quickly reprinted by digital printing).

VII. Notes

Design draft specifications: avoid using RGB mode (printing will cause color cast), text needs to be curved (to prevent font loss), and sufficient bleed space is reserved (to avoid incomplete content after cutting).

Quantity and cost: The larger the batch, the lower the unit cost (offset printing needs to share the plate making fee), and digital printing is recommended for small batches.

Paper and environmental protection: If there are environmental protection requirements, you can choose recycled paper and soy ink, and ask the printer to provide environmental certification (such as FSC, ISO14001).

The core of customized journal printing is "matching needs" - from content presentation to visual texture, it is necessary to take into account practicality and brand tone, and enhance the reading experience and communication effect through detailed craftsmanship.