Products Description

Customized magazine printing is a comprehensive service that integrates content planning, visual design, printing technology and distribution logic. It is mostly used for corporate internal publications, industry information, brand promotion, community publications, etc. Compared with notebooks and journals, customized magazines pay more attention to "narrative of graphic and text collaboration" and "periodicity/batch". Its printing process and detailed design must take into account both the content presentation effect and the reader's reading experience. The following is a detailed introduction from four aspects: core process, key elements, common scenarios and precautions:

I. The core process of customized magazines

The process of customized magazines is more complicated than that of ordinary printed products. It needs to combine the "content production cycle" and "printing timeliness". The core can be divided into four steps: "demand planning → content editing and design → printing production → distribution and delivery", especially emphasizing the coordination of early content and design:

Demand planning

Clearly define the core positioning of the magazine and set the tone for subsequent links:

Attributes and cycles: clarify whether it is an internal corporate publication (monthly/quarterly), industry magazine (bimonthly), brand brochure (one-time) or community publication (semi-annual), the cycle directly affects the printing frequency and production plan;

Content direction: determine the core columns (such as information, interviews, cases, advertising, etc.), target readers (determine the depth and style of the content, such as industry magazines are more professional, and corporate internal publications are more life-oriented);

Specifications and scale: size, number of pages (usually 48-128 pages, must be a multiple of 4 for easy binding), circulation (minimum order quantity 500-1000 The larger the batch, the lower the unit cost);

Budget and cycle: The cost of a single volume is affected by paper, process, and number of pages (e.g., the cost of a full-color 100-page magazine is about 5-20 yuan per volume), and the printing cycle of a single batch is 10-15 days, which needs to match the publishing cycle (e.g., monthly magazines need to be started 1 month in advance).

Content editing and design

The core value of a magazine lies in its content, and this link is the key to customization:

Content editing: Collect text (interviews, reports, reviews), pictures (photography, illustrations, charts), and must go through three levels of review (first draft → editing and proofreading → final review) (avoid typos and copyright issues);

Layout design: Design the layout according to the content style, including:

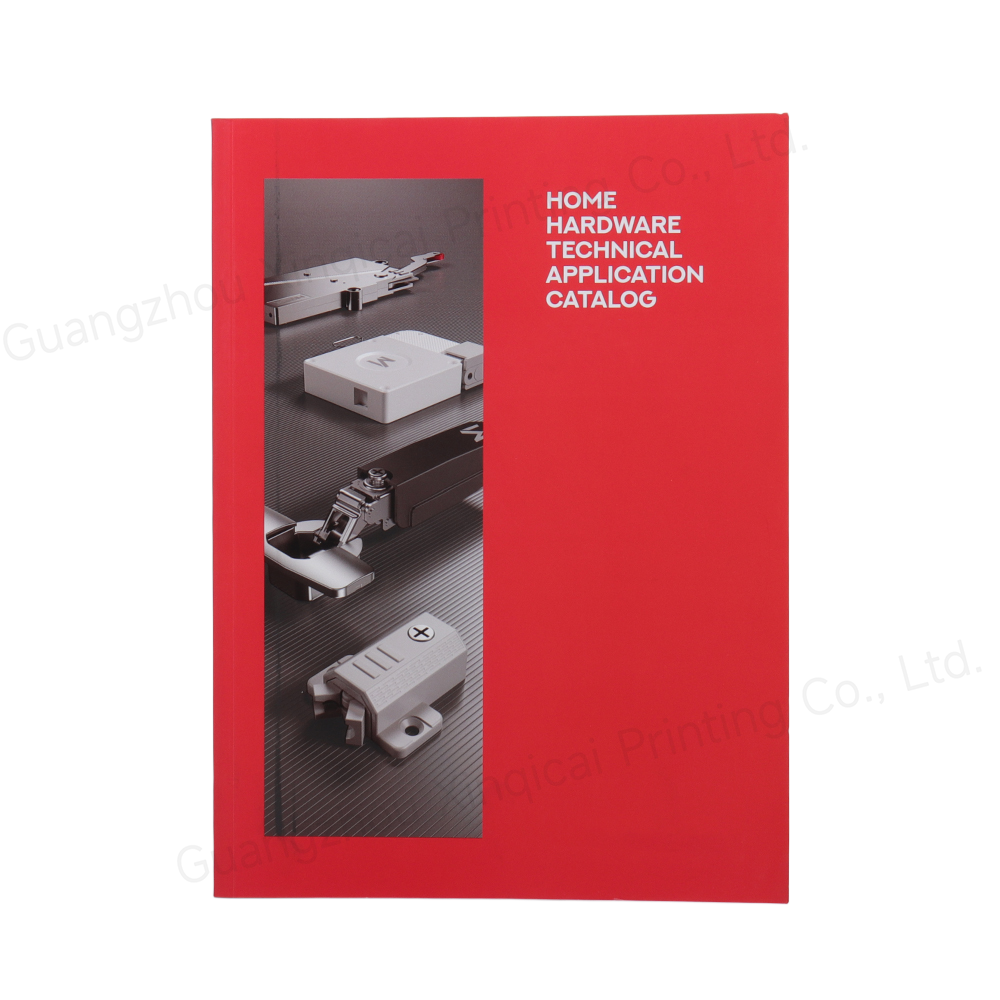

Cover (name, issue number, main visual image, which must highlight recognition);

Inner pages (column division, graphic layout ratio, font size, to ensure smooth reading);

Advertisement pages (if there are commercial advertisements, the layout must be reserved and designed in a unified style);

File output: The design draft is converted into a printed file (PDF format, CMYK mode, resolution 300dpi, bleed 3mm), ensuring that the graphics are clear and the colors are accurate.

Printing and production

Based on the characteristics of magazines with "dense graphics and many pages", the printing process needs to focus on paper, technology and binding:

Paper cutting (cutting cover and inner page paper according to size);

Printing (mainly full-color printing of inner pages, high-precision color printing of cover);

Post-processing (cover lamination, hot stamping, etc. to enhance texture);

Binding (select thread binding, glue binding, etc. according to the number of pages to ensure firmness).

Distribution and delivery

After printing, it is distributed in batches according to distribution needs (such as corporate internal publications distributed to various departments, industry magazines mailed to subscribing customers), and supports on-demand reprinting (for reprinting needs).

II. Core elements of customized magazines (differentiated details)

The customized details of magazines need to be designed around "reading experience" and "content presentation", and the core elements are as follows:

1. Size specifications

The size of the magazine needs to match the content volume and portability, common specifications:

16-page (mainstream): 210×285mm (close to A4, suitable for content with equal emphasis on pictures and texts, such as corporate internal publications and industry magazines);

Large 16-page: 215×297mm (wider layout, suitable for high-end brand promotion magazines, such as luxury goods and real estate publications);

32-page: 140×203mm (small and portable, suitable for light reading magazines, such as club briefings and member communications);

Special sizes: such as square (210×210mm), long strips (suitable for vertical field information, such as art and design), need to be cut separately.

2. Paper selection

Paper directly affects the printing effect (especially the degree of image restoration) and feel, and it is necessary to distinguish between the cover and the inner pages:

Cover paper:

Coated paper (157-250g, smooth and bright white, suitable for printing high-definition pictures and bright colors, commonly used in corporate internal publications and fashion magazines);

Matte pink paper (157-250g, matte texture, avoid reflection, suitable for text-intensive covers, such as industry journals);

Special paper (such as texture paper, kraft paper, with retro or high-end texture, suitable for niche cultural magazines).

Inner page paper:

Coated paper (80-128g, suitable for magazines with a high proportion of pictures, such as photography and fashion, with good color restoration);

Matte pink paper (80-105g, suitable for content with balanced text and pictures, no reflection when reading, such as corporate internal publications);

Light coated paper (70-80g, low cost, suitable for universal magazines with a large circulation, such as community publications).

3. Printing and technology

Magazines have high requirements for "visual impact", and printing and technology need to be controlled:

Printing technology:

Inner pages: full-color offset printing (four-color printing, restore the color of the picture), some details (such as text) can be printed with spot colors (to ensure color uniformity);

Cover: high-precision offset printing, support gradient color, large-area color block printing, and pay attention to color saturation (avoid color cast).

Post-processing (mainly cover):

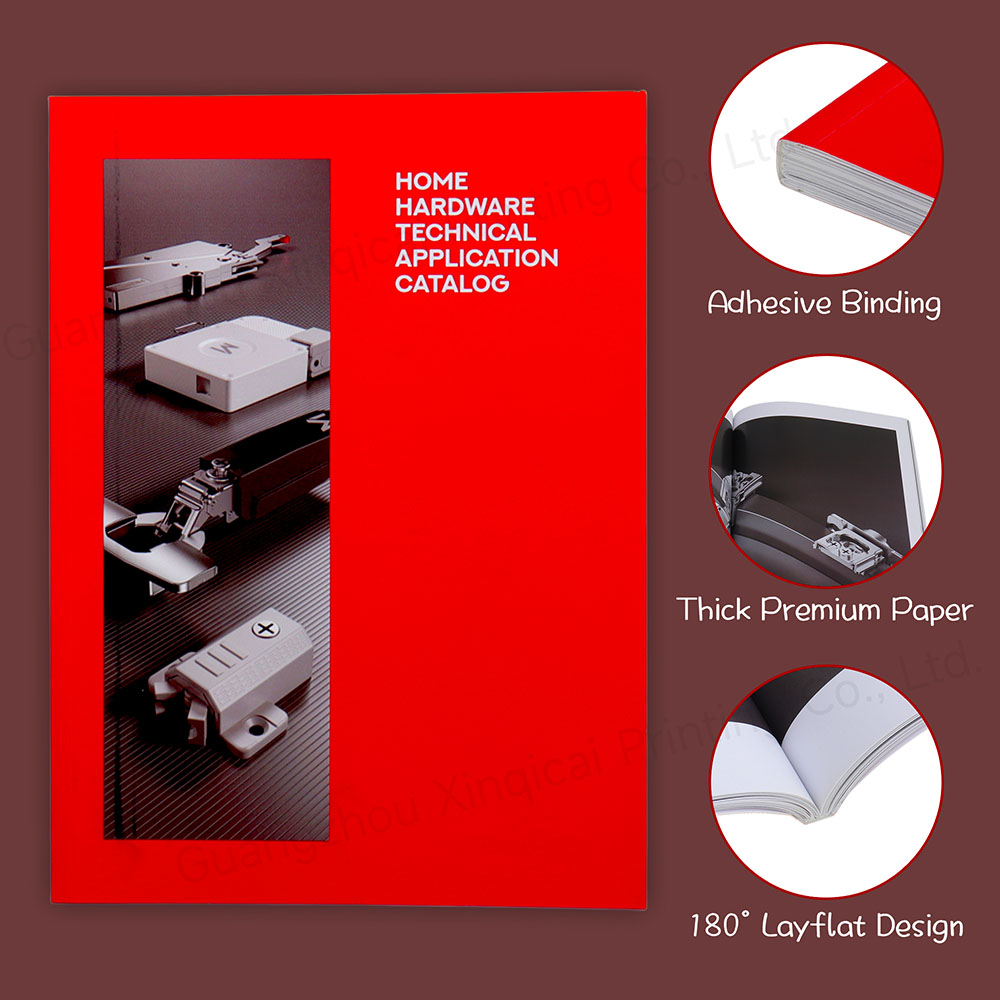

Basic technology: lamination (bright film/matt film, waterproof and scratch-resistant, extend service life), embossing (textures are pressed by molds, such as cloth texture and leather texture, to enhance touch);

Exquisite technology: hot stamping/hot silver (metal foil hot stamping of magazine name or LOGO, enhances high-end feeling, suitable for brand magazines), UV (local varnish bulge, highlighting key patterns or text), embossing/debossing (no ink, three-dimensional texture formed by pressure, low-key and high-end);

Special technology: die-cutting (cover cut into special shapes, such as rounded corners and wavy edges, to enhance recognition), laser hot stamping (metal foil with laser effect, suitable for magazines for young groups).

4. Binding method

Magazines usually have more than 48 pages, and the binding needs to take into account both firmness and flat reading experience:

Sewn binding (recommended): After the inner pages are folded in the order of page numbers, the book is locked with thread, and then glue is applied to the cover. The advantage is that it can be completely laid flat and not easy to fall apart, which is suitable for thick magazines with more than 100 pages;

Glued binding: After the inner pages are folded, the cover is directly glued and pasted. The cost is lower than the sewn binding, but the thick books are prone to "page peeling", which is suitable for thin magazines with 48-80 pages;

Saddle stitching: Fold the book from the middle and nail it to the fold with wire. It is only suitable for very thin magazines with less than 32 pages (such as club briefings). It has the lowest cost but poor firmness. 5. Inner page layout design

The core value of a magazine lies in its content, and the layout needs to take into account both "logic" and "aesthetics":

Column division: Clearly define fixed columns (such as preface, information, interviews, cases) and temporary columns (such as special reports) to form a reading rhythm;

Image-text ratio: images account for 30%-60% (adjusted according to positioning, fashion magazines have a high proportion of images, and industry magazines have a high proportion of text), and images must be high-definition (avoid blur);

Blank space and grid: Reasonable blank space should be used to avoid crowding, and the grid system should be used to unify the layout (such as font, line spacing, and margin consistency) to enhance professionalism;

Advertisement page design: If commercial advertisements are included, they must be coordinated with the style of the inner pages (color or font can be unified) to avoid abruptness.

5. Common scenarios for customized magazines

Most of the scenarios for customized magazines are related to "information transmission" and "brand/cultural communication". Typical scenarios include:

Corporate internal publications: internal publications (such as monthly and quarterly) used by companies to convey values, team dynamics, and employee stories, and enhance cohesion (for example: "Employee Growth Magazine" of Internet companies);

Industry magazines: focus on a certain industry (such as education, medical care, and technology), publish policy interpretations, technology trends, and corporate cases, and serve industry practitioners (for example: "China Construction Industry Information");

Brand promotion magazines: publications used by brands to convey concepts, product stories, or lifestyles (not for sale, mostly for free subscription), and enhance brand tone (for example: "Life Aesthetics Magazine" of luxury brands, "Community Culture Magazine" of real estate projects);

Community/Institutional Publications: publications of schools, associations, public welfare organizations, etc., conveying activity dynamics and member works (for example: university journals, "Image Magazine" of photography associations);

Member magazines: exclusive publications for paying members, providing exclusive content (such as preferential information, customized services), and enhancing member stickiness (for example: "Healthy Life Guide" of gyms).

III. Precautions for custom magazine printing

Content and copyright control:

The text must be proofread more than 3 times (to avoid typos and information errors), especially key information such as data, names, and positions;

The copyright of the pictures must be ensured (use original pictures, genuine library materials or obtain authorization to avoid infringement disputes).

Prediction of printing effect:

Color difference: There is a color difference between the electronic screen (RGB mode) and printing (CMYK mode). It is recommended to proofread in advance (print 1-2 samples) to confirm the color restoration (especially the cover and important pictures);

Clarity: The image resolution must be ≥300dpi (lower than this value will be blurred), and the text font size must be ≥6pt (to avoid being too small to cause reading difficulties).

Balance between cost and circulation:

The larger the circulation, the lower the cost per copy (e.g., the cost per copy of 1,000 copies is 15%-20% lower than that of 500 copies). It is recommended to estimate the circulation according to actual demand to avoid excessive inventory;

When cost is sensitive, paper can be optimized (80g matte paper instead of 105g coated paper for inner pages) or the process can be simplified (hot stamping is cancelled and only lamination is performed).

Matching the cycle with the publication frequency:

The conventional printing cycle is 10-15 days. If it is a periodic magazine (such as a monthly), the process needs to be planned in advance (such as finalizing the manuscript on the 1st of each month and completing printing before the 15th) to avoid delays in publication;

Emergency reprinting requires communication with the printing factory in advance (equipment and materials are reserved). The expedited cycle can be compressed to 5-7 days, but the cost will increase by 20%-30%.

Prioritize reading experience:

Avoid excessive pursuit of craftsmanship that affects usage (e.g., a cover that is too thick to be spread flat, or inner pages that are too thin to be printed through);

The number of pages must be reasonable (too many pages may cause readers to give up reading, too few pages may result in thin content), and 48-96 pages are recommended (taking into account both content volume and portability).

The core of customized magazine printing is to "make the content more convincing" - through the design of size, paper, and craftsmanship, the presentation of text and pictures is more in line with readers' habits, while conveying the tone of the brand or organization. Choosing a manufacturer with experience in journal printing (need to check past cases) and clarifying the details of the requirements (especially the cycle and content direction) in the early stage is the key to ensuring the final effect.