Products Description

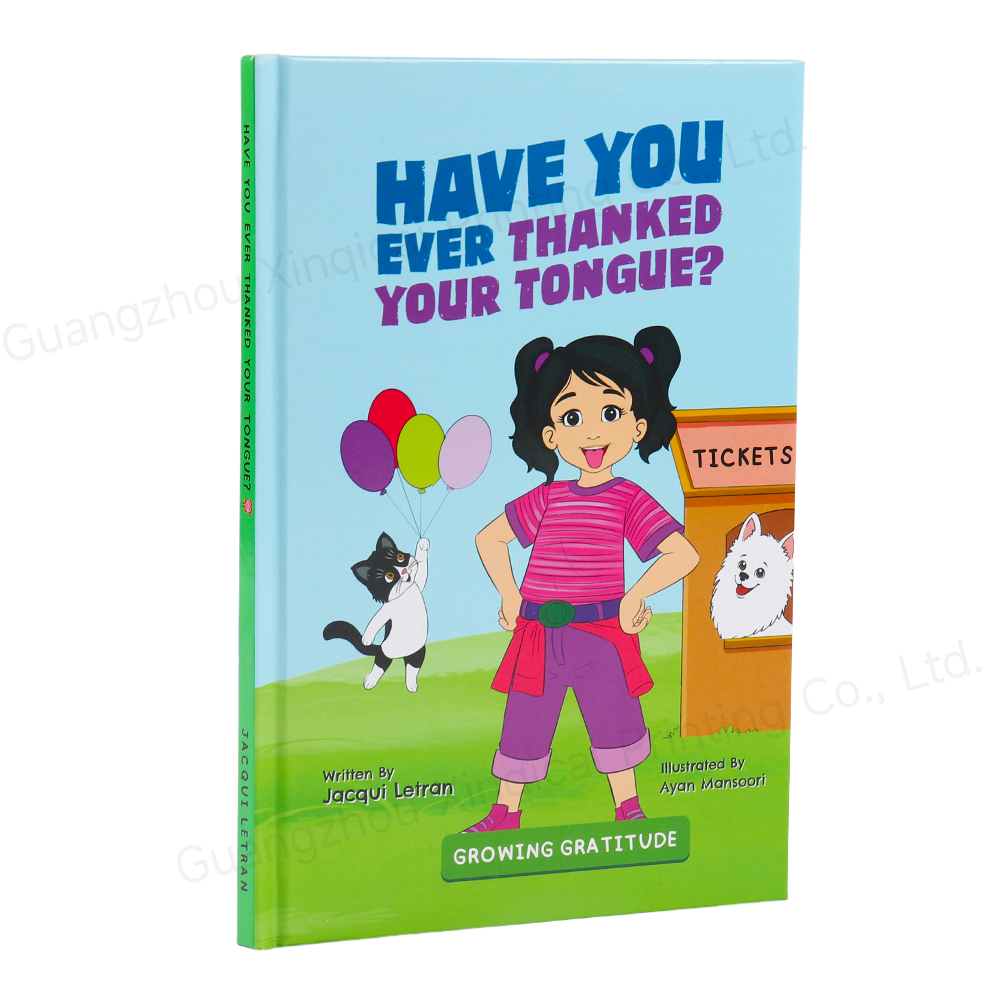

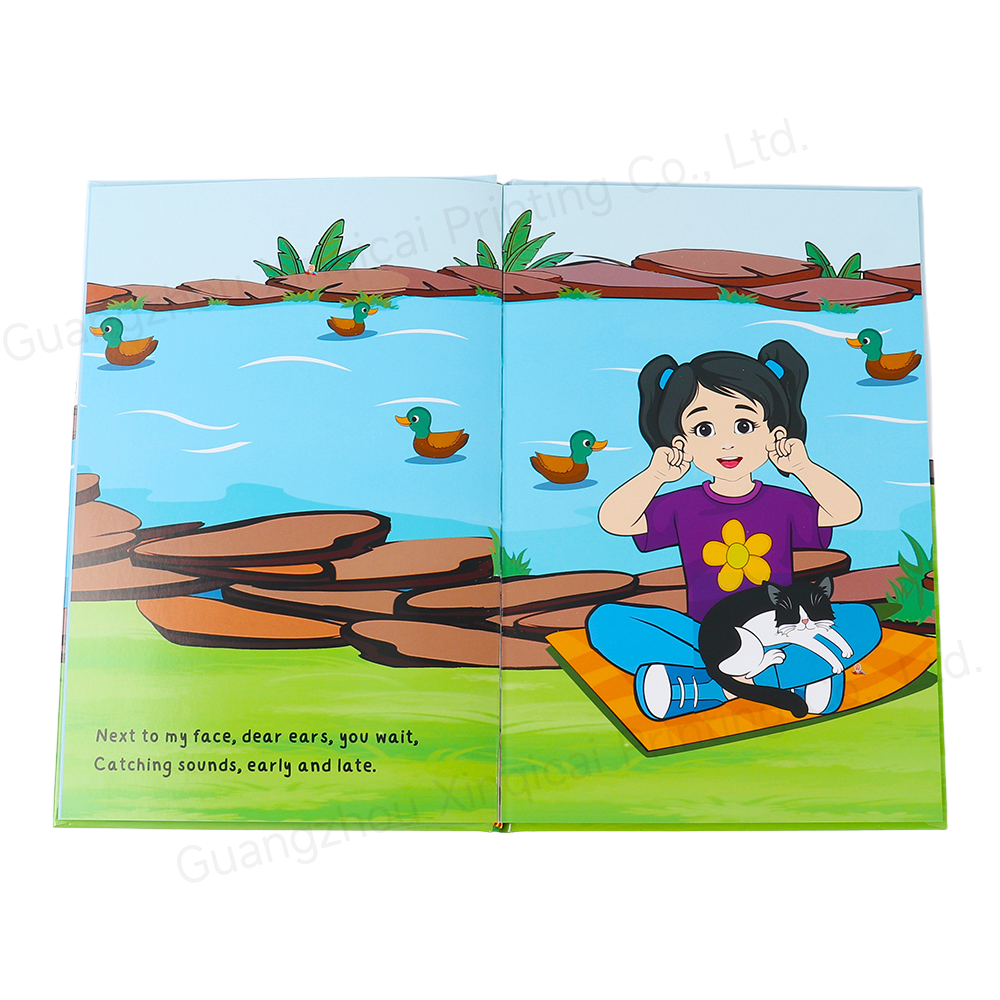

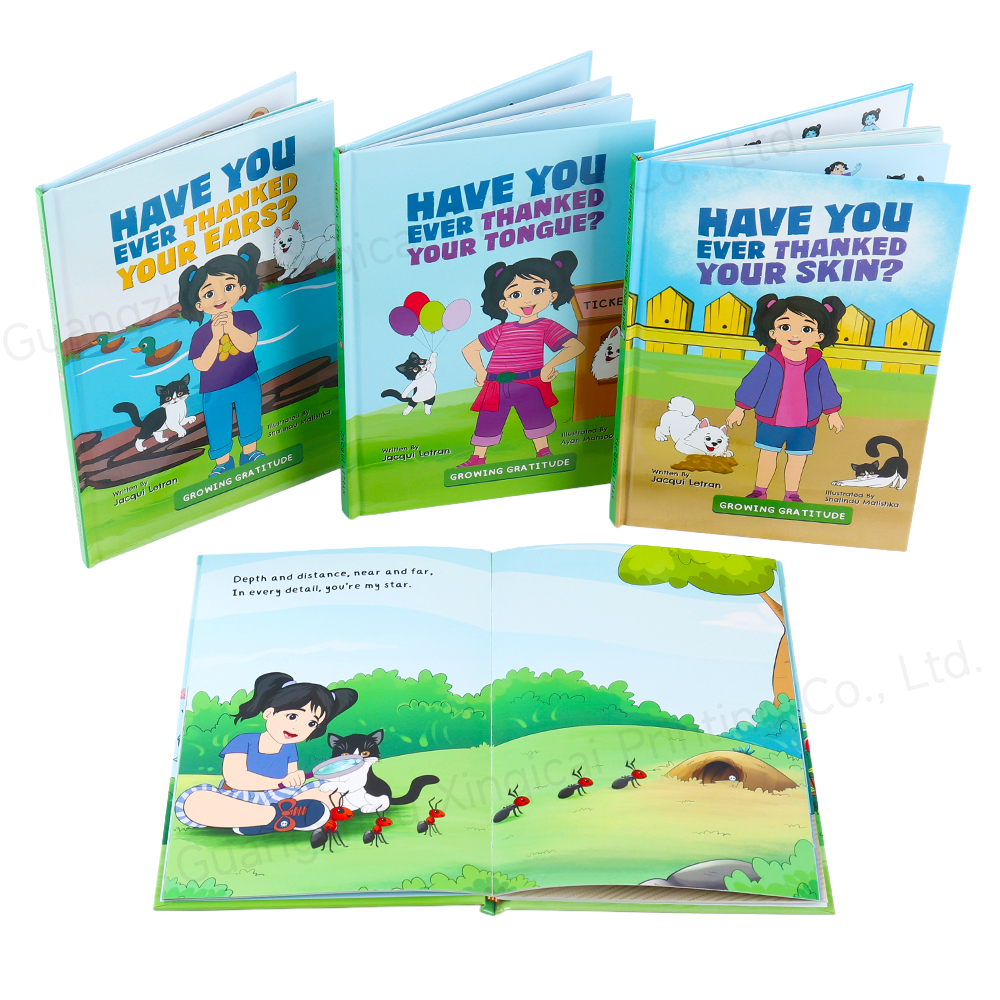

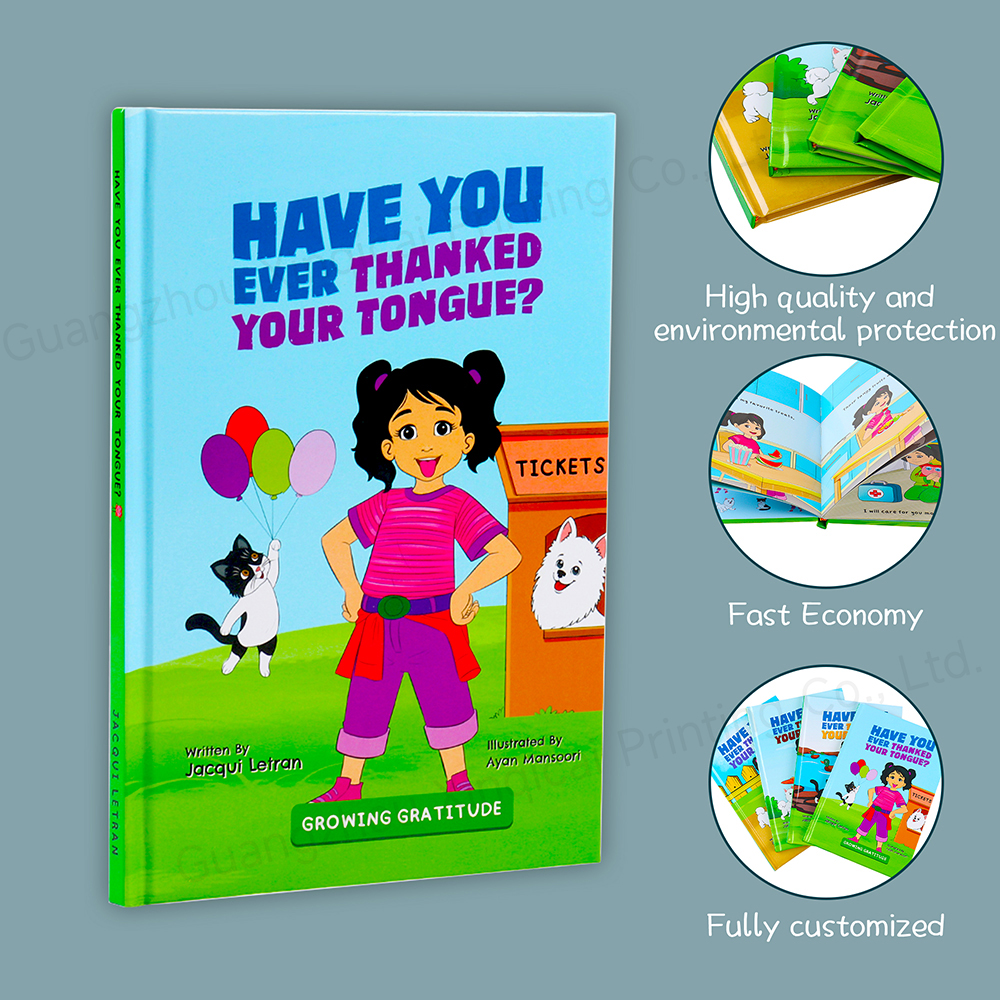

Detailed introduction: Customized children's book printing

Customized children's book printing is significantly different from ordinary book printing. Its core is to focus on children's physiological characteristics (such as uncoordinated hand movements, strong curiosity), cognitive needs (color sensitivity, love of interaction) and safety requirements (no risk of injury), and requires targeted optimization in terms of materials, processes, and designs. The following is a detailed introduction from the aspects of core features, key links, and precautions:

I. Core features of customized children's books

The audience of children's books is minors aged 0-12, so printing must meet three core needs:

Safety: Avoid sharp corners, toxic materials, and small parts that are easy to fall off to prevent scratches, accidental swallowing or allergies;

Interesting: Attract attention through color, touch, and interactive design, in line with children's cognitive habits of "learning through play";

Durability: To cope with children's frequent flipping, tearing, and even biting, it must have wear and tear resistance.

II. Key links in customizing children's books

1. Preliminary preparation: clarify needs and positioning

Before customization, the core elements of the book must be clearly defined to provide a basis for the subsequent selection of printing processes:

Target age group:

Young children (0-3 years old): mainly for cognitive enlightenment, need to be "tear-proof and bite-proof", focus on touch and large color blocks;

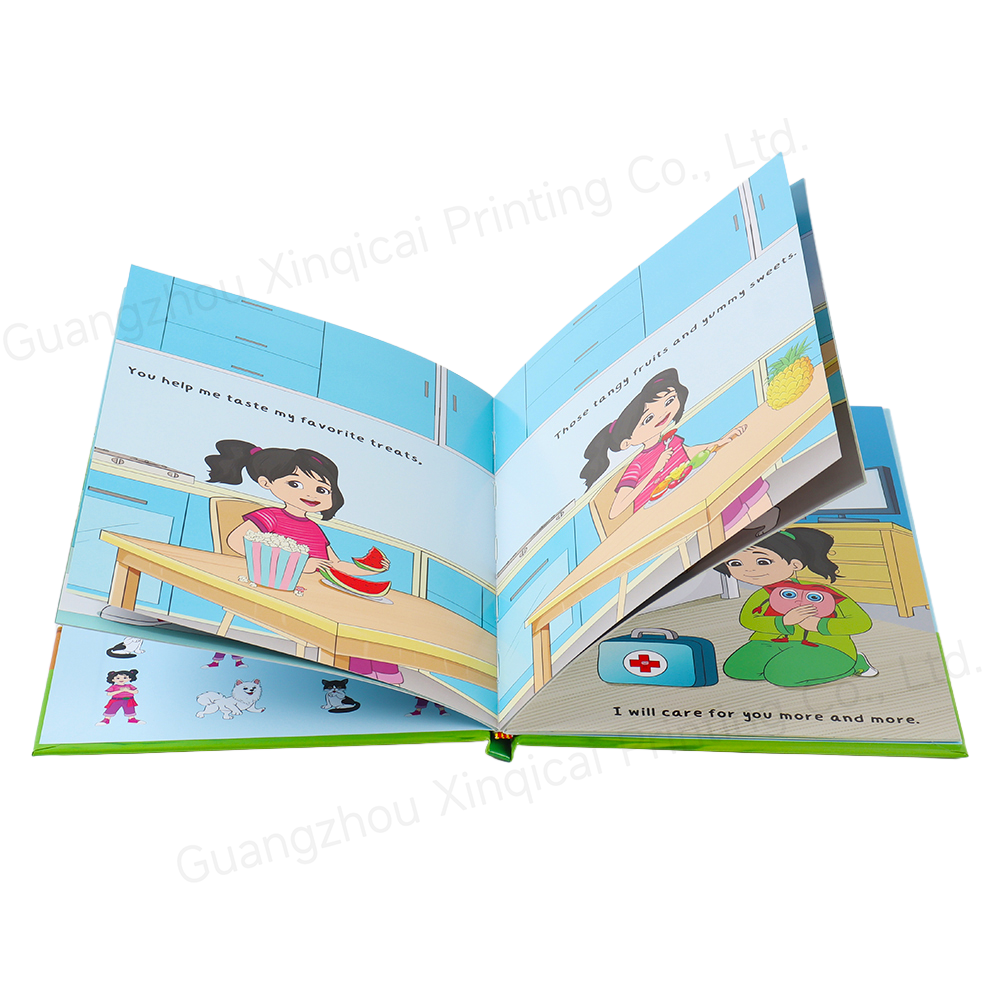

Preschool children (3-6 years old): focus on storytelling and interactivity, can add flip pages and three-dimensional structure;

School-age children (6-12 years old): prefer reading materials that combine pictures and texts, and have higher requirements for text clarity and layout comfort.

Content and theme: Education (cognition, popular science), story (picture books), interactive (game books, sticker books), etc. The theme determines the illustration style (cartoon, realistic, hand-painted, etc.) and layout logic.

Book size and size: It needs to be adapted to the size of children's hands. Common book sizes include 24 (small and easy to hold), 16 (stretched pictures), or special-shaped books (such as animal shapes, toy shapes) to increase fun.

2. Printing process selection: Considering both color and interactivity

Children are highly sensitive to color and like to explore through "touch". The printing process needs to highlight visual appeal and tactile experience:

Basic printing:

Four-color printing (CMYK): the mainstream choice, which can restore bright colors and is suitable for full-color illustrations, ensuring that skin color, animal and plant colors are real and natural;

Special color printing: for specific high-saturation colors (such as gold, silver, fluorescent colors), enhance visual impact (such as printing the cover title with special gold).

Special processes (enhancing interaction and texture):

UV process: Apply a layer of varnish to parts (such as eyes and buttons of cartoon characters) to form a raised bright surface to enhance the touch and three-dimensional sense;

Gold/silver hot stamping: Use metal foil to hot stamp on the cover or illustration to enhance the texture (such as the title and LOGO of hardcover picture books);

Concave and convex embossing: Make the pattern concave or convex (such as animal hair and leaf texture) through mold pressing, which is suitable for touch cognition of young children;

Die-cutting process: Cut the pages into special shapes (such as circles, animal outlines), or die-cut small holes on the pages (such as "seeing the world through small holes") to increase the fun of exploration.

3. Material selection: the core of safety and durability

Material is the basis of the safety and durability of children's books, and environmental protection and physical properties should be given priority:

Paper selection:

Cover material:

Young children: 300-400g thick cardboard (such as coated paper mounting), or kraft paper, special paper (such as tactile paper, velvet paper), with lamination (bright film/matte film) for waterproof and anti-fouling;

Old children: 157-250g coated paper or matte powder paper, taking into account both texture and cost.

Inner page material:

Young children: 200-300g coated paper (thick and crisp), or "tear-resistant paper" (polyethylene material, waterproof and tear-resistant, suitable for bathing books);

Old children: 128-157g coated paper (light and easy to turn), or pure paper (reduce reflection and protect eyesight).

Special materials (enhanced interaction):

Suede paper (simulating the touch of animal fur), sandpaper (simulating bark texture), transparent PVC (superimposed images, such as "perspective body structure"), cloth (cloth book, suitable for young children to chew), etc.

Ink and auxiliary materials:

Environmentally friendly soybean ink or food-grade ink (no heavy metals, no volatile harmful substances) must be used, with little odor, and there is no safety risk even if children lick it; the adhesive must choose environmentally friendly EVA glue to avoid formaldehyde release.

4. Post-processing: Ensure safety and functionality

Post-processing directly affects the safety and user experience of books, and focuses on the following links:

Binding method:

Young children: threading glue binding (firm and not easy to fall off) or loose-leaf binding (convenient to replace inner pages), avoid saddle stitching (easy to fall off, with sharp corners);

Three-dimensional books/flip books: need to use mounting technology (multi-layer paper pasting) to enhance stiffness, and use invisible glue (without affecting appearance) to fix the interactive structure.

Edge processing: All pages must be rounded (radius ≥ 3mm) to avoid scratching hands at right angles; thick cardboard books need to be edged (to remove burrs).

Special structural processing:

Flip pages: dig holes on the pages and paste small flip pages (such as "turn over the stone to see the bug"), which require precise die-cutting and pasting to ensure smooth flipping;

Three-dimensional pages: fold the paper to form a three-dimensional shape (such as a pop-up castle or animal), and calculate the paper thickness and folding angle to avoid structural collapse;

Sticker pages: reserve blank pages and match them with self-adhesive stickers (use environmentally friendly glue to avoid residue).

5. Quality control: safety and experience meet the standards

Environmental testing: must comply with the national "Toy Safety Part 1: Basic Specifications" (GB 6675.1-2014) and "Printing Hygiene Requirements" (GB 18586-2001), focusing on the detection of ink heavy metals (lead, cadmium), formaldehyde, and volatile organic compounds (VOCs) content;

Physical safety testing:

Tear resistance test: young books must be able to withstand a tensile force of ≥5N (about 500g weight) without tearing;

Component firmness: small components such as three-dimensional structures and stickers must pass the "tensile test" (≥9N tensile force without falling off) to prevent children from swallowing them by mistake;

Edge smoothness: run your fingers across all corners, no burrs, no scratches;

Color and clarity: illustrations must be bright and uniform in color (color difference ≤ΔE2), and text must be clear without ghosting (font size ≥12pt, young children ≥16pt) to avoid visual fatigue.

III. Customization scenarios and common types

Different customization needs correspond to different printing solutions:

Publishing houses/children's book brands: mass customization of series picture books (such as popular science picture books, fairy tale collections), focusing on standardized production and cost control, and commonly using four-color printing + binding;

Educational institutions: customized teaching aids books (such as literacy cards, math game books), which need to be combined with interactive design (such as writable inner pages, magnetic stickers), and commonly use special paper + lamination;

Corporate gifts: customized gifts for maternal and child brands and toy stores (such as brand IP picture books), focusing on brand exposure, and commonly using hot stamping/UV technology to enhance texture;

Personal customization: family commemorative albums (such as baby growth picture books), small batch printing (≤50 books), suitable for digital printing (flexible adjustment of content, no need for plate making).

IV. Notes

Design for printing: illustration files must be in CMYK mode (to avoid color difference after RGB to CMYK conversion), with a resolution of ≥300dpi (to ensure clarity); the feasibility of the three-dimensional structure must be communicated with the printing factory in advance to avoid the design failing to be implemented;

Cost balance: special materials (such as velvet paper) and complex processes (such as three-dimensional pages) will increase the cost by 30%-50%, and the plan needs to be adjusted according to the budget (such as digital printing for small batches and offset printing for large batches);

Qualification selection: Choose a manufacturer with a "publication printing license" to ensure content compliance; give priority to manufacturers with experience in children's book printing (familiar with safety standards and process details).

In short, the core of customized children's book printing is "child-centered". Starting from the three dimensions of safety, fun, and durability, the appropriate materials, processes, and processing methods are selected in combination with target needs, and ultimately a "good-looking, good-to-touch, easy-to-use, and safe" children's book is achieved.